Why HANÁK

HANÁK

Interior Concept

We will produce furniture of the highest quality, with uniform design, material and colour, including the interior doors, for all of your interior areas..

One home. One brand. This is HANÁK Interior Concept.

A family tradition dating back to 1926

1926

Josef Hanák

Josef Hanák begins manufacturing custom furniture. From the beginning, he does not back away from the quality of workmanship and thus becomes known to the great personalities of his time. He produces furniture, for example, for Tomas Bata's villa in Zlín, thus creating the foundations for the future tradition of the family business.

1990

Renewal of the HANÁK tradition – foundation of the SH Kroměříž company

The son of Josef Hanák, Ing. Stanislav Hanák, his wife Maria and their children launched the company SH Kroměříž. In the beginning, their 500 m2 workshop was primarily used for the production of hall stands, tables and chests of drawers made of solid pine

2000

HANÁK NÁBYTEK, a.s.

An important milestone for the family is the year 2000, when the company became a joint-stock company, expanded its sales network in the Czech Republic and gradually expanded to other foreign markets.

2020

30 years of premium quality

The company is celebrating 30 years since the family tradition was revived. the experience is passed on to the 4th generation of Hanák descendants. However, the main idea remains the same: „We are convinced that quality is the future of our company.“

Ing. Stanislav Hanák

From design to realization

Idea

We create your home. Based on your preferences, our architects and designers will design the ideal furniture model in the right combination of materials and colours so that the interior is perfectly matched and meets all your needs. Proper ergonomics is a matter of course.

Visualisation

A visualisation that reflects future reality. We will develop a realistic picture of your dream interior. We will fine-tune the smallest details into the final form. Detail makes the whole.

Realizations

The implementation phase, directed by our professional assembly team, goes hand in hand with the architect's detailed design. A real interior is created, where the individual parts of our high-quality furniture are combined into the whole that makes your home. One home. One brand.

State-of-the-art technology lines in one place

The most modern furniture-producing factory in the Czech Republic

Our technological leadership and production capacities enable us to realise both individual and large-scale production for development projects.

We are one of the best equipped furniture manufacturing companies in Europe.

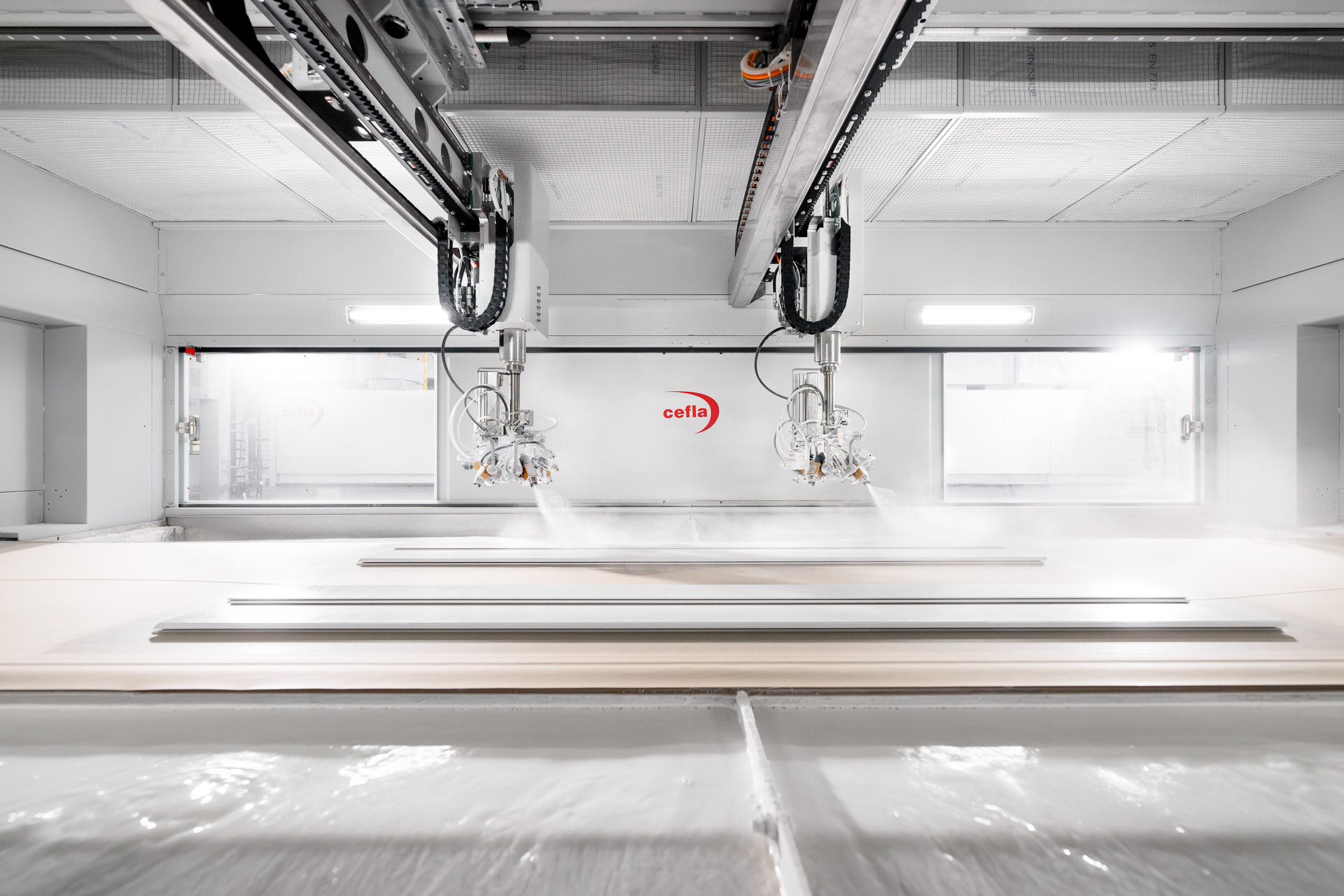

Centre for the application of NANO varnishes

The most modern painting centre for the application of NANO varnishes in Europe ensures the highest quality surface treatment of furniture, without the slightest human intervention in the coating process.

Varnishing takes place under the monitoring of thousands of special sensors, checking the maximum accuracy of production.

The length of the coating centre is 50 metres.

Robotic painting

Only robotic painting ensures that paint is evenly sprayed on each part of the furniture element, which creates a perfectly painted and durable surface.

We apply transparent or pigmented NANO varnishes from a deep 5% matt to a 100% high gloss.

Assembly robotic line

A place where complete units are created from individual parts.

Robotic furniture assembly technology ensures perfect assembly of furniture modules to one tenth of a millimetre. The assembly precision will be reflected in the final appearance and functionality of the furniture after the assembly of the work.

Premium quality

and sustainability

„Design and quality for generations" - the motto we follow throughout our business. We produce quality and sustainable furniture, the lifespan of which exceeds its possible obsolescence.

Our furniture is passed from generation to generation, thus contributing enormously to the often-discussed topic of ecology and sustainability.

We care about nature very much, which is why we produce products that serve you for decades.

![[Translate to Angličtina:]](/fileadmin/user_upload/proc_hanak/hanak-nabytek-vyroba-zdravotni-nezavadnost-zdravi_kopie.jpg)

Health and safety

We care about your health, which is why, since the 1990s, we have continuously fought to restrict the release of carcinogenic formaldehyde from furniture into the interior environment.

We precisely define the nature of the input materials and glue each part of the furniture using SLIM-LINE technology, thus preventing the emission of even a negligible amount of formaldehyde into the air.

We repeatedly achieve results that are several times below the required EU standard.